ITEC Systems BV received a million-euro contract to develop and deliver an innovative and modern crate handling and sorting system for packaged chicken products.

Client:

InterChicken BV, Bodegraven, The Netherlands

Manufacturers of consumer chicken products.

operation:

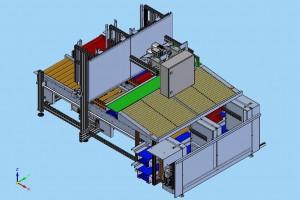

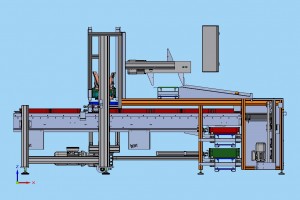

The system consists of a stack of boxes marked for loading vans, lift systems with acceptance transport buffer Entstaplersysteme of boxes and an unloading station of the packaged goods. The packages will be placed on a weight determination and labeling unit. and then the labeled products are automatically transported to a sorting system with a large number of customer locations. Empty crates are automatically guided relative to the product level. This works for various CBL crates. Rejection system of the filled trays are conveyed to a case stacker station and stacked. The final stack of crates are transported automatically by means of a stack of boxes shuttle to a lift for 2 stacks of crates and then the expedition made, ready for transport.

InterChicken and ITEC system work together with the company Espera (weighing and labeling) (pricing) and COD (ERP software) order to be sure that this (machine / installation), it is possible millions makes packaged chicken products to be weighed annually to label and sorting per customer.

InterChicken is a supplier with a full range of chicken and poultry products. The company has set itself the objective of realizing the needs of consumers in Concepts for retail and wholesale, and

ITEC designs and builds machines to measure the customer’s request and consists of a team of experienced, practical set, technical specialists. The group has extensive experience in analyzing situations of production and – systems and working out concrete suggestions for improvement. Both the design, construction, management and operation or the integration of the production situation will be entirely self-determination carried out at the customer.

It may here be an adaptation to an existing production system, or even a complete new production or packaging line.

ITEC operates mainly in the Netherlands and neighboring countries. But in Italy, Finland and the USA already projects were realized.